The technology validation of the Open Innovation Test Bed is based on pre-defined demonstration cases from complementary markets, ranging from biosensor development through molecular diagnostics and smart phone-supported home diagnostics to pharmaceutical tests and sensors for monitoring bioprocesses:

DEMO CASE 1

Biosensors for Food Safety &

Public Health Monitoring

Development of a molecular diagnostics assay for the multiplexed detection of SARS-CoV-2 and Influenza as well as the employment of aptamers for the detection of contaminants in food.

The production of the individual components of biochemical and molecular diagnostics assays and microfluidic systems like sensor chip and foils, surface functionalization and spotting will be scaled up. These developments lead to a simulation-based assay design and microfluidic and sensor channel library, both easily customizable to the needs of different assays and readout platforms, fluidic structuring of low-autofluorescence materials such as COP and novel materials such as biodegradable thermoplastics and self-powered fluidic actuation with disposable micropumps and microvalves.

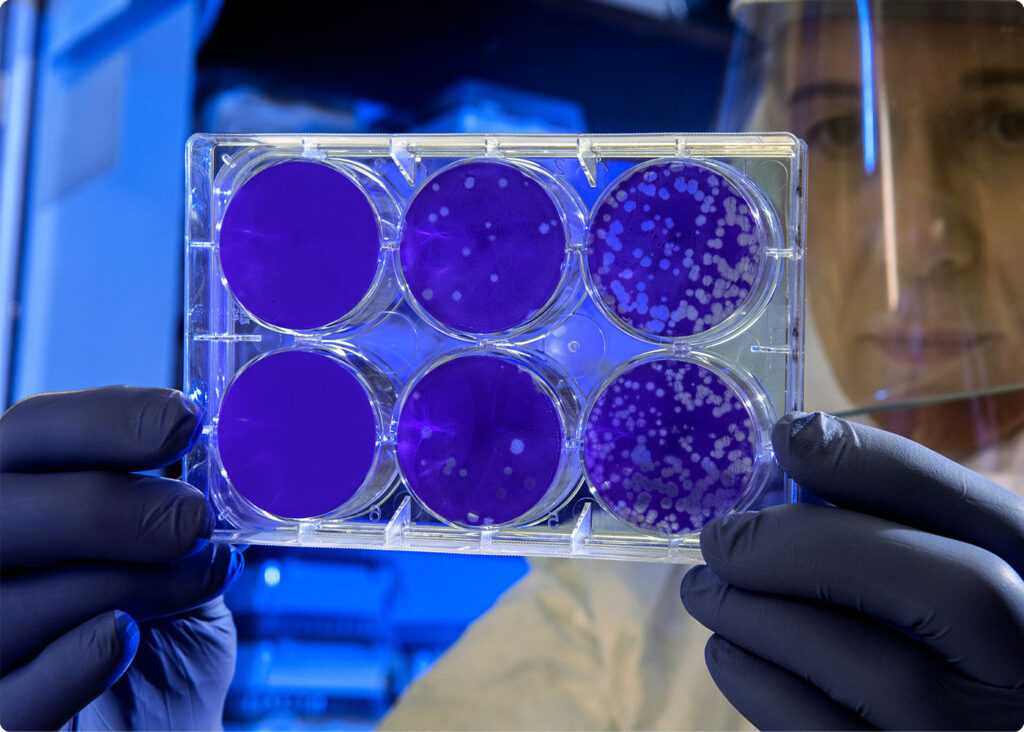

DEMO CASE 2

Molecular Diagnostics

for Sars-CoV-2

Sensor chip production for a molecular recognition platform in medical diagnostics in general and for Sars-CoV-2 diagnostics (both antibody and viral genetic material testing) in particular.

The platform uses a polymer foil chip with reaction chamber and capillary pump. So, foil based microfluidic chips for in-vitro diagnostics (IVD) will be upscaled to TRL7 for the first time. Moreover, a full roll-to-roll based process flow, including the process steps imprinting, biomolecule printing, inlet cutting and lamination will be set-up. In addition, the full value chain including implementation of IVD regulations (ISO 13485, European medical device regulations (MDR)) will be implemented.

DEMO CASE 3

Smart Phone Enabled Home Diagnostics for Potassium in Blood

Ion sensitive sensors for home diagnostics with user friendly smartphone based read out and for PoC diagnostic instruments.

The devices consist of printed ion-selective sensors on polymer films and integrated into microfluidic structures for sample loading and calibration. Such microfluidic sensor cartridges can be used either in readout instruments for clinical and point-of-care diagnostics or as fully self-contained sensor test stripes for home diagnostics. The foil based sensor stripes for home care are then combined with a microelectronic chip for wireless sensor readout with smartphones. The cartridges for home care integrate a plasma separation membrane which separates plasma from a drop of capillary blood.

DEMO CASE 4

Cell Culture Devices

for Pharmaceutical Testing

Microfluidic chips for neuron cell culture and axon outgrowth monitoring, to investigate the formation and function of neural networks

A roll-to-roll based manufacturing process will replace injection moulding with UV imprinting. This allows to realize smaller microfluidic channel sizes and additional functionalities like electrodes. For the first time micro structuring, electrode printing and surface modification will be applied to the microfluidic chip in the same production process. The application of new production techniques enable a scale-up of chip manufacture. Axon outgrowth assays therefore become accessible to high through put screening.

DEMO CASE 5

Sensors for

Bio-Process Monitoring

Microfluidic biosensors for monitoring the activity and stability of enzymatic extracts derived from enzymatic fermentation processes

A microfluidic biosensor for monitoring the activity and stability of enzymatic extracts derived from enzymatic fermentation processes will be scaled-up. The disposable kit will be tested for inline monitoring and closed loop control of enzyme production. This will allow monitoring of enzymatic activity and stability in bio-certified enzyme production, which is currently not possible with any commercially available tool.